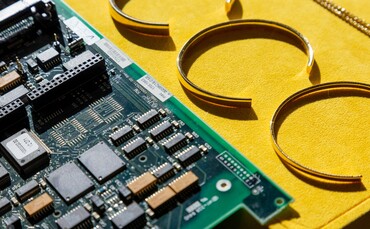

The Royal Mint has today unveiled plans to convert high quality sustainable gold extracted from TV, laptop, and mobile phone circuit boards into luxury jewellery at a new factory in South Wales.

According to Britain’s oldest company, the 3,700 square metre facility will use patented “world-first” technology from Canadian firm Excir to extract gold from up to 4,000 tonnes of printed circuit boards found in discarded electronic items each year.

The factory has deployed Excir’s innovative technology at industrial scale for the first time in a move the Royal Mint claims will offer a new, more sustainable way to “mine” high-quality 999.9 purity gold for use in the Mint’s luxury jewellery collection, 886 The Royal Mint.

E-waste-derived gold products sold by The Royal Mint include pendants, rings, and earrings, as well as made to order necklaces and chokers.

The World Gold Council estimates recycled gold is around 10,000 times less greenhouse gas intensive than mined gold.

According to the United Nations’ latest Global E-waste Monitor, the amount of discarded tech is also growing by 2.6 million tonnes every year, with a record 62 million tonnes of e-waste produced in 2022 – up 82 per cent from 2010.

A recent study by non-profit Material Focus found precious materials such gold, silver, and copper contained inside millions of electrical items that are either hoarded, thrown away, illegally exported, or stolen could add £927m to the UK economy.

“The Royal Mint is transforming for the future, and the opening of our Precious Metals Recovery factory marks a pivotal step in our journey,” said Anne Jessopp, chief executive at The Royal Mint.

“We are not only preserving finite precious metals for future generations, but we are also preserving the expert craftmanship The Royal Mint is famous for by creating new jobs and reskilling opportunities for our employees. We have ambitious plans, and I am proud that we are safeguarding The Royal Mint for another 1,100 years.”

The decline in the use of cash has been a catalyst for innovation and diversification at The Royal Mint, a process accelerated after the original maker of UK coins closed its overseas currency division earlier this year. All 230 staff in the division have been offered roles in new and growing business areas, including the Precious Metals Recovery factory.

The Royal Mint has also been actively engaging with major sector bodies to help produce an industry first International Organization for Standardization (ISO) standard for the definition of recycled gold, helping to provide clarity to the industry, consumers, and stakeholders on how to access sources of recycled gold.

“The factory underpins our commitment to using sustainable precious metals and providing a new source of high quality, recovered gold,” said Sean Millard, chief growth officer at The Royal Mint. “It allows us to reduce our reliance on mined materials and is another example of how we’re working to decarbonise our operations.

“Our commitment to growth, innovation and circular economy principles shapes an exciting and more sustainable future for The Royal Mint, our people and our communities.”

Keep up to date with all the latest green business news by signing up to the free Daily and Weekly BusinessGreen Newsletters.