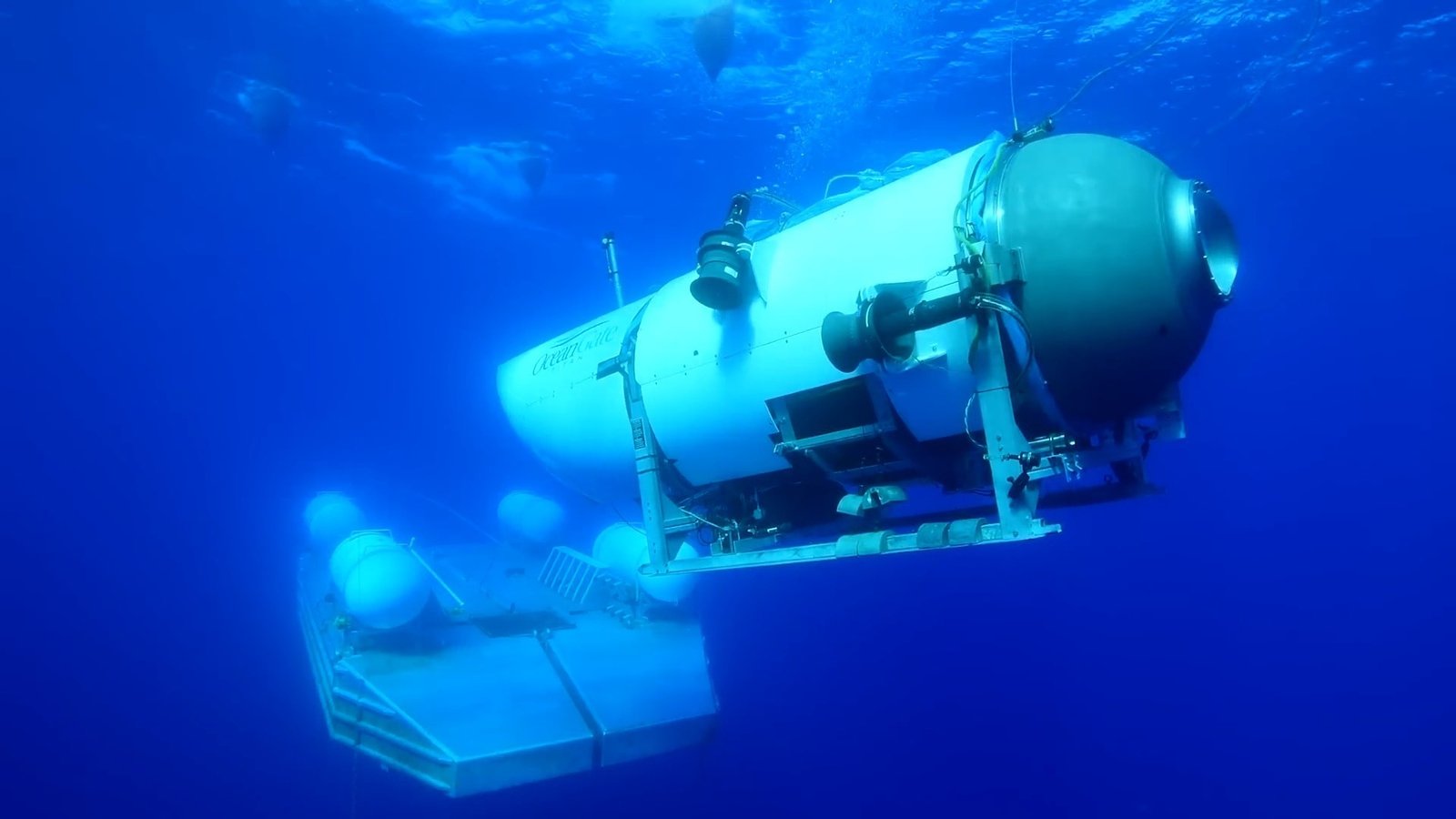

The carbon fibre hull of the experimental submersible that imploded en route to the wreckage of the Titanic had imperfections dating to the manufacturing process, an engineer with the National Transportation Safety Board has said.

Engineer Don Kramer also told a Coast Guard panel that the hull behaved differently after a loud bang was heard on one of the dives the year before the tragedy

He said there were wrinkles, porosity and voids in the carbon fibre used for the pressure hull of the Titan submersible.

Two different types of sensors on Titan recorded the “loud acoustic event” that earlier witnesses testified about hearing on a dive on 15 July 2022, he said.

Hull pieces recovered after the tragedy showed substantial delamination of the layers of carbon fibre, which were bonded to create the hull of the experimental submersible, he said.

OceanGate co-founder Stockton Rush was among the five people who died when the submersible imploded in June 2023.

Mr Kramer’s statements were followed by testimony from William Kohnen, a long-time submersibles expert and key member of the Marine Technology Society.

Mr Kohnen emerged as a critic of OceanGate in the aftermath of the implosion and has described the disaster as preventable.

He pushed back at the idea the Titan could not have been thoroughly tested before use because of its experimental nature.

“We do have these test procedures. They are enshrined in law,” Mr Kohnen said.

The Coast Guard opened a public hearing earlier this month that is part of a high-level investigation into the cause of the implosion.

Some of the testimony has focused on the submersible’s carbon fibre construction, which was unusual. Other testimony focused on the troubled nature of the company.

Coast Guard officials noted at the start of the hearing that the submersible had not been independently reviewed, as is standard practice.

That and Titan’s unusual design subjected it to scrutiny in the undersea exploration community.