Despite there being divisive opinions on the use of hookless rims in road cycling, they are some of the newest technologies appearing at this year’s Tour de France – but they’re far from being the dominant trend in the pro peloton, with hooked rims still a common sight.

While hookless wheels – with a straight vertical edge that removes the rims bead hooks – are said to offer advantages in terms of aerodynamics and weight savings, safety concerns and regulatory discrepancies continue to fuel debate about their adoption. We’ve taken a look at why the pro wheel manufacturers sponsoring pro teams use – or don’t use – this technology, and what it might mean for the future of racing and bike wheel safety.

Who’s riding hookless rims at the 2024 Tour de France?

Let’s start by looking at which men’s pro teams are riding on hookless wheels this year. In essence, out of the 22 WorldTour pro men’s teams six are riding on hookless rims, while the rest of the peloton relies on the more traditional, hooked design:

- Lotto Dstny: Zipp

- Movistar: Zipp

- Team Jayco–AlUla: Cadex

- Team Visma–Lease a Bike: Reserve (semi-hooked)

- Team TotalEnergies: ENVE

- UAE Team Emirates: ENVE

While Zipp, ENVE and Cadex are fully embracing hookless, Reserve is a bit of an in-betweener and says on its website: “Currently, the limiting factor for hookless rims is tyre compatibility and a limit on tyre pressure.

“Full hooked rims on the other hand are typically heavier and harder to install tubeless tyres. Reserve road rims as a result are semi-hooked, which means there are reasonable limits on tyre pressure, no tyre incompatibility issues and tyres are easy to install.”

Reserve is getting ahead of us in referring to both the pros and cons of hookless wheels, but let’s first see how the other brands reason their rim design decisions.

> 10 tech trends to copy off the Tour de France pros

Zipp and ‘hookless-gate’

Zipp, despite some well-documented incidents earlier this year, continues to supply the Lotto Dstny and Movistar riders with the brand’s hookless wheels. Lotto Dstny, however, has also been seen using Oquo wheels, the in-house brand from their bike provider Orbea.

Perhaps undeservedly, Zipp ended up being a wheel brand in the eye of the hookless storm, following Thomas De Gendt’s crash. Back in April, we spoke with Zipp’s product engineers to ask them if hookless rims are here to stay – despite the negative press – and whether consumers should worry about compatibility issues following issues in the pro peloton. The overarching message was that there is no reason to worry.

“We have four years of history of riders using 28mm road bike tyres on our 25mm internal rims. While we see some tyre fitment issues there, it’s not a large number at all. And so we feel that if you’re using 28 on a 25 successfully, feel free to continue to use that,” Zipp said.

The compatibility conundrum

Much of the conversation following De Gendt’s tyre coming off at the UAE Tour was about the ETRTO and ISO standards – both of which had been updated for the current pro cycling season. The newest standards state that a 28mm tyre is not compatible with a 25mm internal rim width (whether it is hookless or hooked) in UCI-sanctioned races. A 29/30mm tyre, however, is compatible with a 25mm internal rim width.

When it comes to tyre widths though, it’s not quite as simple as looking at the side of the tyre to figure out what the width of it is. A 28mm tyre will measure differently on a 19mm internal width rim than it would on a 25mm wide rim. And though the pros are increasingly using wider tyres, they might not all still be wide enough on certain rims.

> Why wider tyres on road bikes are here to stay

ETRTO requires that 28mm (stated) tyres should measure 28mm on a 19mm internal rim width, and 30mm (stated) tyres should measure 30mm on a 21mm internal rim width. If you take these requirements to real life, you will find that the casing width on a 28mm tyre can be close to, if not identical to, a 30mm tyre of the same make/model. This begs the question… why is one safe and the other isn’t?

Following that controversial crash, the UCI released the following statement:

“In the short term, the UCI reminds teams and riders of the requirement set out in article 1.3.018 of the UCI Regulations, which imposes compliance with International Organisation for Standardisation (ISO) standards 5775-2:2021 and 5775-1:2023 in cycling competitions. These standards provide a framework for the compatibility of tyre and rim widths on bicycles. The UCI notes that the norms defined in these ISO standards have not always been respected and does not rule out the possibility that this may have been a contributing factor in some of the incidents encountered.”

But if you think that all this sounds like a lot of jargon… the UCI admits that there is room for improvement in forming a more cohesive rim and tyre compatibility standard:

“The UCI also recognises that compliance with the ISO standards by teams and riders is made more difficult by the fact that manufacturers base their recommendations for compatibility between tyres and rims on the recommendations provided by the European Tyre and Rim Technical Organisation (ETRTO), which have not always been aligned with ISO standards.”

Thus, given the muddled nature of compatibility tables and the lack of universal standards for road tyres that work on hookless wheels, it appears most teams have decided to steer away from them because of the uncertainty.

As you might have started to gather, the standardisation of tyres and rims can seem convoluted… and that’s because it is. Though tyre manufacturers have to comply with regulations, those don’t include ensuring compatibility with all wheels. This means that a certified, approved tubeless tyre might not be safe with all hookless rims. This has then led brands to create compatibility charts on their websites, detailing which tyres they have found safe on their rims.

> Buyer’s guide to tubeless tyres

Zipp for example, still listed plenty of 28mm tyres – even 25mm – to be compatible with its 25mm hookless rims when we spoke to them in April. A the time, the brand said it would not alter its recommendations: “We want to make sure everything is correctly placed before we make a change or if we make a change”, Zipp said.

Since then, Zipp has made changes to its compatibility chart and effectively ruled out compatibility of 25mm internal width wheelsets with anything narrower than a 29mm tyre. There are a few exceptions to this, for example, the Schwalbe Pro One TLE 700×28 is still listed as compatible with the brand’s hookless 353 NSW race wheels. We’ve asked Zipp for comment on whether their advice to the consumers using sub-29mm tyres still applies, and won’t hold our breath waiting for an answer…

Similarly, Giant-owned Cadex has a compatibility chart based on in-house testing that rules out using 28mm Continental GP5000 TL and Specialized Roubaix Pro 2Bliss tyres in the same width.

While it’s good the brands show the compatibility charts, it’s evident that it is hard for a consumer to be sure that their tyres will be ok on the hookless rims. You can’t simply buy a set of hookless wheels and be certain that whatever tubeless tyres you have will work. Unsurprisingly, the Giant-equipped Team Jayco–AlUla is relying heavily on Cadex in all of its finishing kit, including tyres, to ensure full compatibility.

And that, perhaps, is the reason pros also rely on what is safer and more reliable across the board: hooked rims. Even if marginal gains matter, perhaps the risks of mechanical failures are deemed too high.

How did hookless rims become a thing?

By now, you might be interested in how the hookless design became a thing in the first place if it seems so complicated. Traditional hooked rims have been a staple in cycling, featuring a small lip on the inner edge of the rim that secures the tyre bead in place. This design has effectively prevented tyre blow-offs and maintained tyre security at high pressures. However, the late 2000s and early 2010s saw the emergence of hookless rims, largely driven by advancements in manufacturing techniques and material science.

> Have we witnessed the death of tubular tyres?

Similarly to tubeless tyres, hookless rim is a relatively new technology in the cycling world, that has trickled into the skinny tyre discipline of road cycling from mountain biking.

The concept is simple: without hooks, the rim design can allow for a more aerodynamic shape and potentially a better tyre-rim interface. This can lead to improvements in speed and performance, both key factors in a race like the Tour de France.

Hookless rims were initially embraced by mountain bikers. This adoption was partly due to the potential advantages hookless designs offered: a reduction in weight, a simplified manufacturing processes, aerodynamic benefits, and improved impact resistance.

Mountain biking, and later gravel cycling, with their lower pressures and wider tyres, were excellent for proving that this new tech could offer an advantage. The chunkier tyres and lower pressures helped alleviate concerns about tyre blow-offs, that are certainly more plausible in road cycling scenarios.

The advantages of hookless rims

One of the primary advantages of hookless rims is the potential for weight reduction. By eliminating the hook, manufacturers can produce slightly lighter rims, contributing to the overall reduction in bike weight. As we know, races such as the Tour de France are all about marginal gains, and there every gram counts.

Hookless rims also offer manufacturing simplification. Without the need for the hooked lip, the production process can be more straightforward, which can lead to reduced costs and production times. Additionally, some hookless rim designs claim aerodynamic benefits, as the smooth inner rim profile can contribute to reduced air resistance.

This might not be an advantage to road cyclists, but added resistance is another benefit of hookless rims. Because they lack the delicate hook edge, which can be prone to damage, they can be more appealing for disciplines like mountain biking and gravel cycling, where rough terrain and impacts are common.

The cons of hookless rims

Despite all those benefits, hookless rims don’t come without their challenges. Without the hook on the rim to keep the tyre in place, ensuring the tyre fit and safety has been a critical issue for hookless rims.

Achieve reliable and safe tyre seating requires precise tolerances and compatibility between rim and tyre designs. This has necessitated the development of new standards and testing protocols to ensure safety and reliability – but there is still no unified, universal compatibility between all tubeless tyres and hookless rims.

Couldn’t you just use tubes? Well, no. Hookless rims require tubeless tyres because their maximum recommended pressure is 72.5PSI, and generally, tubeless tyres have a stiffer bead which allows it to stay on the rim even at these lower pressures.

Dove Tate, the founder of wheel manufacturer Parcours, told us: “One point that’s often overlooked is that imposing a blanket 72psi pressure limit is a limitation for heavier or more powerful riders who would naturally ride a higher pressure. It forces them to ride a wider tyre to maintain this pressure, which can reduce aero performance on a given rim.”

While the industry has been working towards establishing universal standards to address tyre compatibility, as it stands it’s a bit of a Wild West scenario.

Why isn’t everyone using and making hookless wheels?

Although the pros of hookless wheels are clear, there are multiple reasons why certain wheel manufacturers won’t make hookless road bike wheels at all yet. Recently, Roval took quite a strong stance on the matter when it released its new Rapide CLX II Team wheels, which continued to feature a hooked bead:

“We know that hookless wheels can’t perform under our demanding high-pressure testing standards, and any carbon wheel can crack under intense impact, but that’s no excuse for a tyre to blow off.”

Roval supplies wheels to Redbull-Bora-Hansgrohe, as well as Soudal Quick-Step, and as far as the above statement goes, it is a pretty obvious dig at Zipp, that continues to say hookless wheels are unquestionably safe. Similarly DT Swiss, a very renowned wheel manufacturer, doesn’t provide Uno-X Mobility with any hookless wheels for the Tour.

The main reason for wheel brands to steer away from hookless rims is the compatibility and safety issues. Tate says it isn’t making hookless road wheels because there no undeniable benefits for riders.

“As a wheel manufacturer, we only introduce a new technology when we can quantify a benefit for our riders”, says Tate.

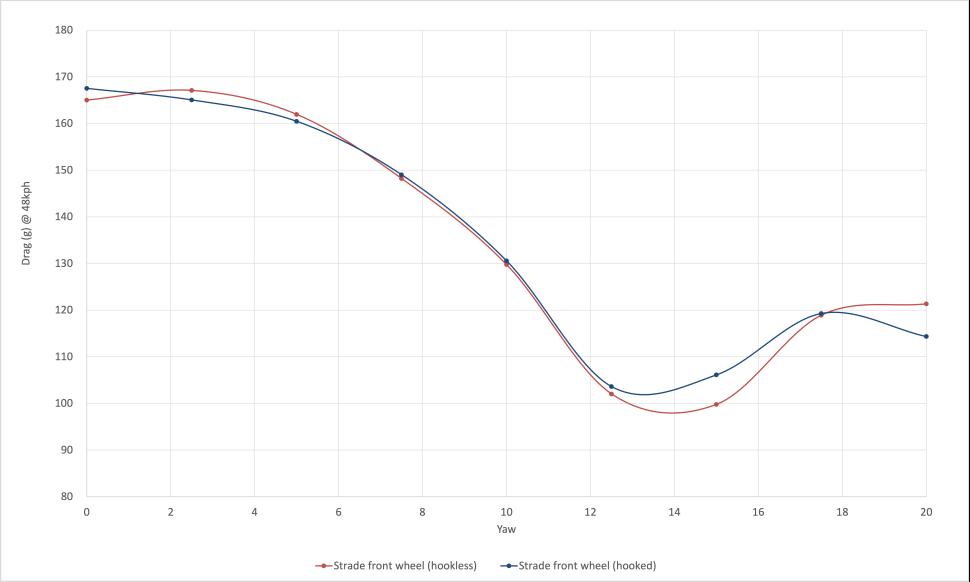

“As far as I’m aware, we’re the only manufacturer to have openly published test data showing a back to back comparison of otherwise-identical hooked vs. hookless rims (where other brands have claimed a performance advantage, there have been other changes between models, e.g. rim depth or profile). For our test, we weren’t able to see any discernible performance benefit.”

It seems quite a few brands think differently, though. German brand Newmen, which provides wheels for Intermarché-Wanty, says on its website: “Hookless rims don’t only have a lot of advantages for cars and motorcycles but also for bicycles: The rim flanges can be designed with less material and therefore less weight and increased durability.

“With tubeless easy/tubeless-ready tyres, the tyre bead stretches so little under normal tyre pressure, that the tyre is safely secured on the rim even without hook. So if you want to be extra safe we recommend using tubeless ready/tubeless easy tyres.

“The diameter of our rims is at the upper limit of the ETRTO-standard. This makes for a secure and safe connection between tyre and rim. All current rims went through our extensive in-house burst pressure testing. In combination with the maximum pressures in the table below, a tubeless tyre blowing off one of our rims is close to impossible.”

Yet, none of the brand’s road bike wheels are hookless. Trek’s componentry brand Bontrager has adopted a similar approach, as none of its road wheels have a hookless profile.

What do you think, will we see ever more hookless rims at the 2025 Tour de France? Let us know your thoughts in the comments.