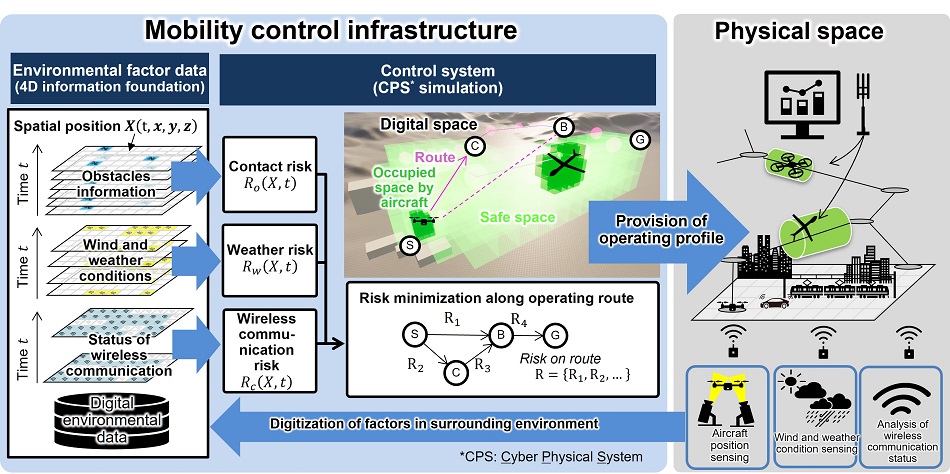

Figure 1 Overview of mobility control infrastructure

Tokyo, March 18, 2024 – Hitachi Ltd. (TSE: 6501; hereafter “Hitachi”) has developed a mobility control infrastructure which achieves a high degree of safety and operational efficiency in transport infrastructure. When automatically or remotely operating mobility devices, the new technology determines environmental changes along a route in real time, such as weather or status of wireless communication, manages them within a digital space to predict subsequent changes, and calculates a safe movement route, thus enabling stable operation. In this way it can provide safe and efficient automatic operation for supporting daily living and recovery activities in disaster-stricken areas. Hitachi intends to use this technology as “air route for mobility” to improve convenience in air mobility for drones and other aircrafts. Also, it can be utilized as a very safe control system for take-off and landing, thereby contributing to safe operation and further automation of transport infrastructure.

Background

As means of transportation of things and people become more diverse, there is a need in transport infrastructure to provide safe and efficient routes. Japan’s Ministry of Economy, Trade and Industry is promoting its Digital Lifeline Development Plan*1, to rapidly resolve multiple social issues and strengthen the foundations of transport infrastructure that is essential for daily living and industrial progress. Air mobility devices like drones, however, are easily affected by changes in the weather and conditions of wireless communication, as well as changes in the surrounding environment such as distances from other devices, buildings, or trees. Because it is not possible to predict sudden changes in these types of environmental factors, there has been a need to visually confirm the safety of the location. Hitachi has used its unique digital twin technology developed for railway solutions and information control systems, to capture these changes in real time and to manage them in a digital space, and has embarked on the development of a new mobility control infrastructure.

About the new technology

The mobility control infrastructure predicts various environmental factors necessary for safe and comfortable operation of all types of mobility devices, and safely and efficiently controls their movement. The new technology addresses the automation of air mobility take-off and landing, which was previously considered difficult due to high susceptibility of devices to environmental factors. The technology can identify in real time changing environmental factors in the vicinity of a take-off and landing site (e.g. information about obstacles, weather and wind conditions, status of wireless communication), predict subsequent changes over time, and configures the optimum route to enable take-off and landing in a digital space, realizing a much safer control system. In particular, the system provides an aircraft that is taking off or landing with a dedicated area (managed in a digital space for the exclusive use of that aircraft), and an operating profile necessary for its remote operation, improving both the safety of the take-off/landing route and operability.

The efficacy of the new technology was verified at an indoor take-off/landing test facility established at the Kokubu factory (Hitachi City, Ibaraki Prefecture), by using several drones that are available on the market. The development team confirmed that wind conditions and other environmental changes during take-off/landing that have been traditionally confirmed visually, were identified and predicted in real time. Operation profiles for suitable timing of take-off/landing (such as between periods of high winds), order of drones, and travel routes were provided in advance. The team also confirmed that smooth automatic take-off/landing were possible at intervals of 1 aircraft every 2 minutes at the shortest, while reducing aircraft wait time (Figure 2).

![[image]Figure 2 Using drones for verification](https://www.hitachi.com/New/cnews/month/2024/03/240318a-2.jpg)

Figure 2 Using drones for verification

Main features

1. Technology for measuring environmental factors and integrating systems

![[image]Technology for measuring environmental factors and integrating systems](https://www.hitachi.com/New/cnews/month/2024/03/240318a-3.jpg)

Integration of information about environmental factors obtained from several sensors located on the ground and from other systems is achieved by combining machine learning from a situational model with the “maximum likelihood estimate method”*2 which uses a learned model. Data is supplemented with real-life information obtained from the sensors and other systems to generate environmental data including that of unobserved areas, changes in environmental factors important to operation (such as the position of mobility devices on the operating route, weather, and wireless communication connectivity) are calculated, and data is updated in real time.

2. Technology for integrating and managing 4D information using a 3D urban model*3

![[image]Technology for integrating and managing 4D information using a 3D urban model](https://www.hitachi.com/New/cnews/month/2024/03/240318a-4.jpg)

Obstacles, weather, and the status of radio waves along the entire operating route are mapped in a digital space and combined with time information to create a 4D information for predicting changes over time, based on the environmental factors obtained above and a 3D urban model. Then, the digital space is divided into isotropic voxels*4 based on 4D spatiotemporal information foundational guidelines*5 published by DADC*6, which enables efficient and frequent updating of changes in environmental factors over a wide area.

3. “Graph-based network”*7 technology to calculate safe routes at high speed

![[image]"Graph-based network" technology to calculate safe routes at high speed](https://www.hitachi.com/New/cnews/month/2024/03/240318a-5.jpg)

Several waypoints are established to consolidate information on difficult-to-operate locations and time of passage, and a graph network is constructed connecting these waypoints. By calculating risk between the waypoints on the graph-based network at high speed, it becomes possible to rapidly extract a safe route that will minimize sum total risk.

4. Technology to configure an occupied area and secure a safe area

![[image]Technology to configure an occupied area and secure a safe area](https://www.hitachi.com/New/cnews/month/2024/03/240318a-6.jpg)

An occupied area is established on the operating route into which other aircraft are not permitted to enter. The occupied area is an aerial space for movement in which it is possible to safely operate as appropriate to environmental changes, given the effects of wind on the performance of each aircraft and what it carries. By combining these occupied areas, each aircraft can be provided with an efficient operating profile. Safe mobility operation is enabled by providing the operating profile to automatic and remote operation systems.

- *2

- Maximum likelihood estimation method: In statistics, a method for point estimates of probability distribution parameters that the data given obey.

- *3

- 3D urban model: 3D map information of buildings, forests and mountains; for example, PLATEAU

(https://www.mlit.go.jp/plateau/). - *4

- Isotropic voxel: A cubic area divided into equal-sided spaces.

- *5

- 4D spatiotemporal information foundational guideline:

https://www.ipa.go.jp/digital/architecture/guidelines/4dspatio-temporal-guideline.html [in Japanese] - *6

- DADC (Digital Architecture Design Center): An institution under the umbrella of the IPA (Information Technology Promotion Agency, Japan) for furthering design of mechanisms and systems that will enable linking and sharing of data necessary to achieve Society 5.0 (the ultra-smart society).

- *7

- Graph-based network: A concept based on graph theory that expresses state transition as a network structure.

Future initiatives

To adapt this mobility control infrastructure to drones and other various automated mobility devices, Hitachi intends to participate in R&D issues selected in the “Autonomous control and decentralized control technologies and detection technologies for multiple small unmanned aerial vehicles, etc. that enhance the safety of airspace use,”*8 which is an R&D concept in the Japan Science and Technology Agency’s “Key and Advanced Technology R&D through Cross Community Collaboration Program (K Program).”*9 Through this initiative, Hitachi will configure the technology necessary for group control, which is essential for large-scale operation of air mobility devices, and to contribute to higher safety and greater efficiency in the movement and transport of things and people.

A part of these deliverables was presented at SAE AeroTech 2024*10, convened from March 12 to 14, 2024. A presentation will also be made at the 11th SICE Multi-Symposium on Control Systems*11 of the Society of Instrument and Control Engineers, to be held from March 17 to 20, 2024.

- *8

- https://www8.cao.go.jp/cstp/anzen_anshin/20221227_mext_3.pdf [in Japanese]

- *9

- https://www.jst.go.jp/k-program/ [in Japanese]

- *10

- Published as “Proposal for relaxation of airspace restrictions based on flight-continuation possibility of UAVs in event of failure.”

- *11

- Published as “Development of a Method to Change Air Mobility’s Flight Paths Using Sky Environment Information.”

About Hitachi, Ltd.

Hitachi drives Social Innovation Business, creating a sustainable society through the use of data and technology. We solve customers’ and society’s challenges with Lumada solutions leveraging IT, OT (Operational Technology) and products. Hitachi operates under the business structure of “Digital Systems & Services” – supporting our customers’ digital transformation; “Green Energy & Mobility” – contributing to a decarbonized society through energy and railway systems, and “Connective Industries” – connecting products through digital technology to provide solutions in various industries. Driven by Digital, Green, and Innovation, we aim for growth through co-creation with our customers. The company’s consolidated revenues for fiscal year 2022 (ended March 31, 2023) totaled 10,881.1 billion yen, with 696 consolidated subsidiaries and approximately 320,000 employees worldwide. For more information on Hitachi, please visit the company’s website at https://www.hitachi.com.

Media Contact:

Hitachi, Ltd.

Research & Development Group

Information contained in this news release is current as of the date of the press announcement, but may be subject to change without prior notice.